-

LQ-BY Coating Pan

The tablet coating machine (sugar coating machine) is used to pills for pharmaceutical and sugar coating the tablets and food industries. It is also used for rolling and heating beans and edible nuts or seeds.

The tablet coating machine is widely used for making tablets, sugar-coat pills, polishing and rolling food demanded by the pharmacy industry, chemical industry, foods, research institutes and hospitals. It can also produce new medicine for research institutions. The sugar-coat tablets that are polished possess a bright appearance. The intact solidified coat is formed and the surface sugar’s crystallization can prevent the chip from oxidative deterioration volatilization and cover the improper flavor of the chip. In this way, tablets are easier to be identified and their solution inside human stomachs can be lessened.

-

LQ-BG High Efficient Film Coating Machine

The efficient coating machine consists of major machine, slurry spraying system, hot-air cabinet, exhaust cabinet, atomizing device and computer programming control system.It can be widely used for coating various tablets, pills and sweets with organic film, water-soluble film and sugar film etc.

The tablets make complicated and constant movement with easy and smooth turn in a clean and closed drum of the film coating machine. The coating mixed round in the mixing drum are sprayed on tablets by the spray gun at the inlet through the peristaltic pump. Meanwhile under the action of air exhaust and negative pressure, clean hot air is supplied by the hot air cabinet and is exhausted from the fan at the sieve meshes through tablets. So these coating mediums on the surface of tablets get dry and form a coat of firm, fine and smooth film. The whole process is finished under the control of PLC.

-

LQ-RJN-50 Softgel Production Machine

This production line consists of main machine, conveyor, drier, electric control box, heat preservation gelatin tank and feeding device. The primary equipment is the main machine.

Cold air styling design in the pellet area so the capsule forming more beautiful.

Special wind bucket is used for the pellet part of the mold, which is very convenient for cleaning.

-

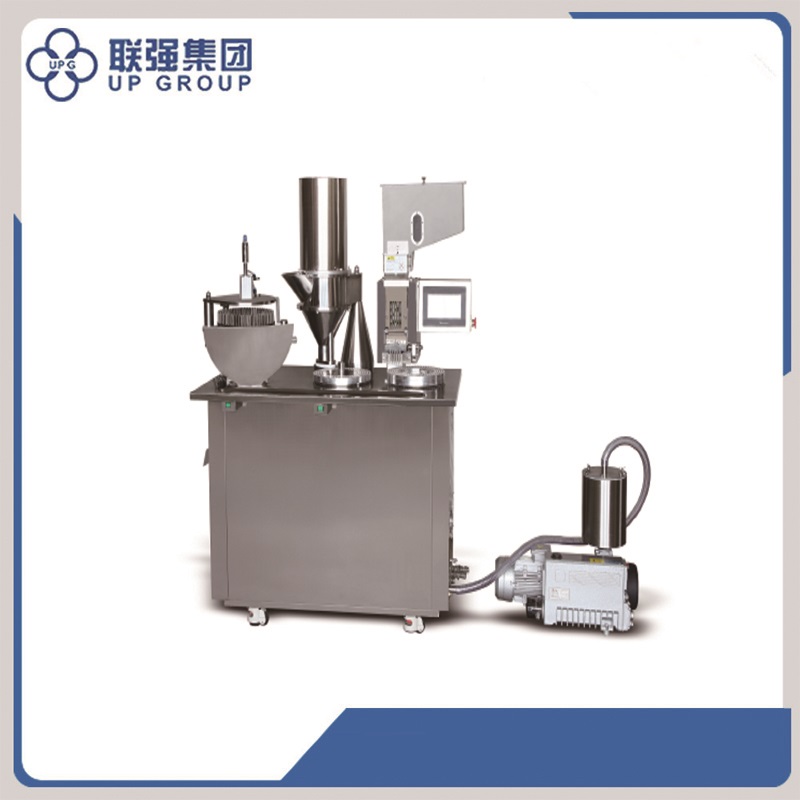

LQ-NJP Automatic Hard Capsule Filling Machine

LQ-NJP series fully automatic capsule filling machine is designed and further improved on the base of original full automatic capsule filling machined,with high technology and exclusive performance. Its function can reach leading level in China. It is an ideal equipment for capsule and medicine in pharmaceutical industry.

-

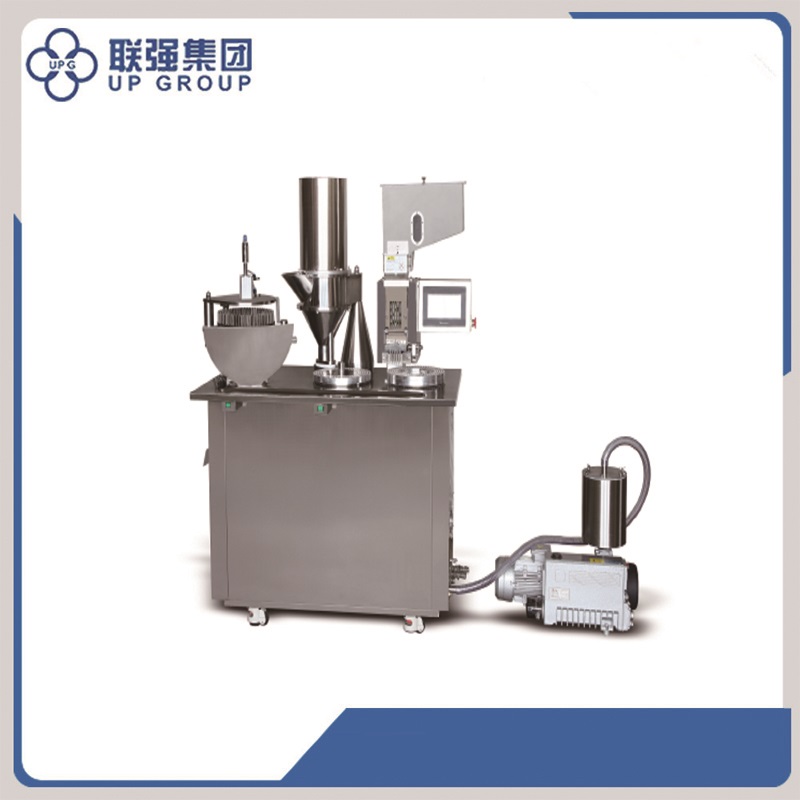

LQ-DTJ / LQ-DTJ-V Semi-auto Capsule Filling Machine

This type capsule filling machine is a new efficient equipment based on old type after research and development: easier more intuitive and higher loading in capsule dropping, U-turning, vacuum separation in comparison with the old type. The new type of capsule orientating adopts columns pill positioning design, which shortens the time in the replacement of mould from the original 30 minutes to 5-8 minutes. This machine is one type of electricity and pneumatic combined control, automatic counting electronics, programmable controller and frequency conversion speed regulating device. Instead of manual filling, it reduces labor intensity, which is the ideal equipment for capsule filling for small and medium-sized pharmaceutical companies, pharmaceutical research and development institutions and hospital preparation room.

-

LQ-TFS Semi-auto Tube Filling and Sealing Machine

This machine applies the once transmission principle. It uses the slot wheel dividing system to drive the table to do intermittent movement. The machine has 8 sits. Expect manually putting the tubes on the machine, it can automatically fill the material into the tubes, heat both inside and outside of the tubes, seal the tubes, press the codes, and cut the tails and exit the finished tubes.

-

LQ-BTA-450/LQ-BTA-450A+LQ-BM-500 Automatic L Type Shrink Wrapping Machine

1. BTA-450 is an economical fully-auto operation L sealer by our company’s independent research and development, which is widely used in mass production assembly line with auto-feeding, conveying, sealing, shrinking in one time. It is high working efficiency and suits for the products of different height and width;

2. The horizontal blade of sealing part adopts vertical driving, while the vertical cutter uses international advanced thermostatic side cutter; The sealing line is straight and strong and we can guarantee seal line in the middle of the product to achieve perfect sealing effect;

-

LQ-BKL Series Semi-auto Granule Packing Machine

LQ-BKL series semi-auto granule packing machine is specially developed for granular materials and designed strictly according to GMP standard. It could finish weighing, filling automatically. It is suitable for all kinds of granular foods and condiments such as white sugar, salt, seed, rice, aginomoto, milk powder, coffee, sesame and washing powder.

-

LQ-BTB-300A/LQ-BTB-350 Overwrapping Machine For Box

This machine is widely applicable to the automatic film packaging (with gold tear tape) of various single boxed articles. With new-type of double safeguard, no need to stop the machine, other spare parts will not be damaged when the machine runs out of step. Original unilateral hand swing device to prevent adverse shaking of the machine,And the non-rotation of the hand wheel when the machine keeps running to secure the security of the operator. No need to adjust the height of worktops on both sides of the machine when you need to replace moulds, no need to assemble or dismantle the material discharge chains and discharge hopper.

-

LQ-LF Single Head Vertical Liquid Filling Machine

Piston fillers are designed to dispense a wide variety of liquid and semi-liquid products. It serves as ideal filling machines for the cosmetic, pharmaceutical, food, pesticide and other industries. They are completely powered by air, which makes them especially suitable for an explosion-resistant or moist production environment. All the components that come in contact with product are made of 304 stainless steel, processed by CNC machines. And the surface roughness of which are ensured to be lower than 0.8. It is these high quality components that help our machines achieve market leadership when compared with other domestic machines of the same type.

Delivery time: Within 14 days.

-

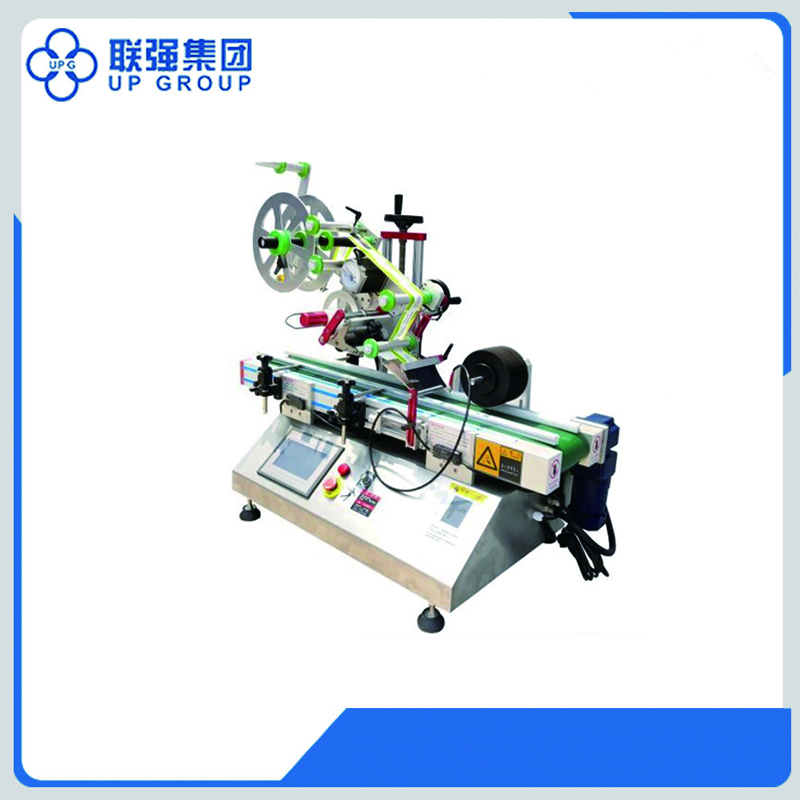

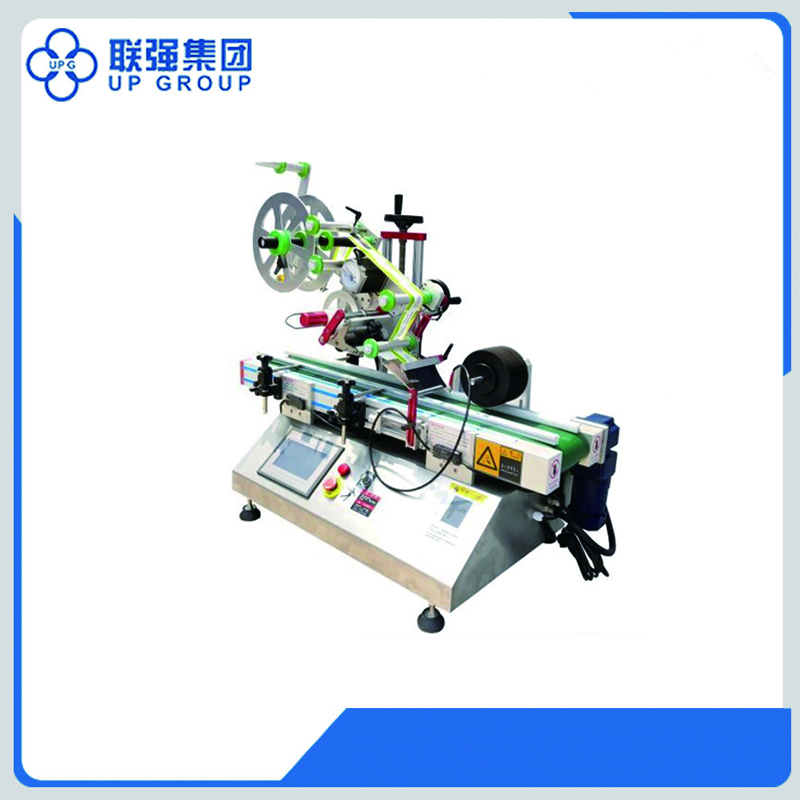

LQ-FL Flat Labeling Machine

This machine is used to label the adhesive label on the flat surface.

Application industry: widely used in food, toys, daily chemicals, electronics, medicine, hardware, plastics, stationery, printing and other industries.

Applicable labels: paper labels, transparent labels, metal labels etc.

Application examples: carton labeling, SD card labeling, electronic accessories labeling, carton labeling, flat bottle labeling, ice cream box labeling, foundation box labeling etc.

Delivery time: Within 7 days.

-

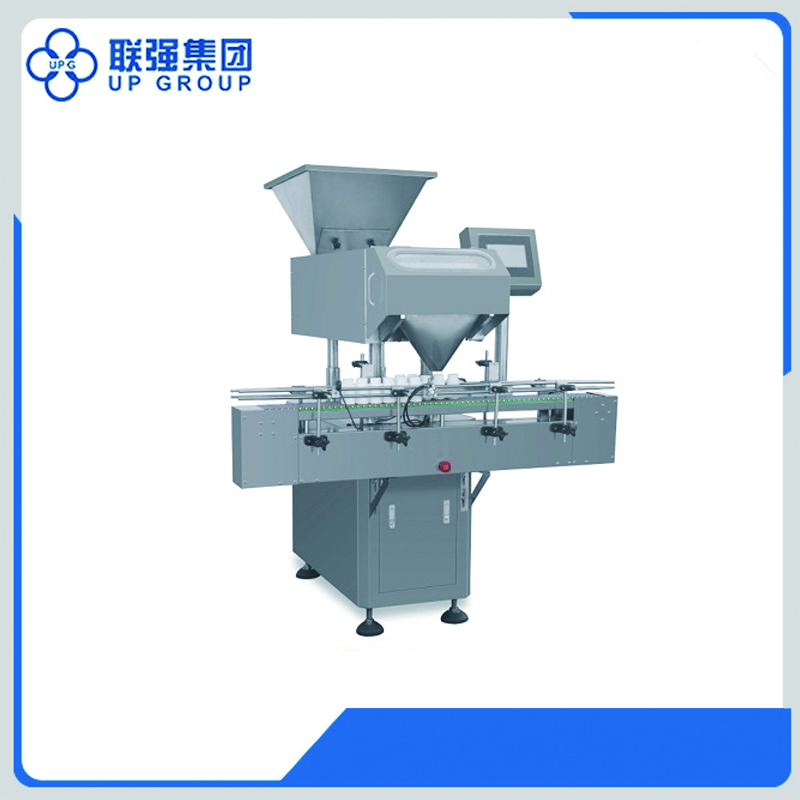

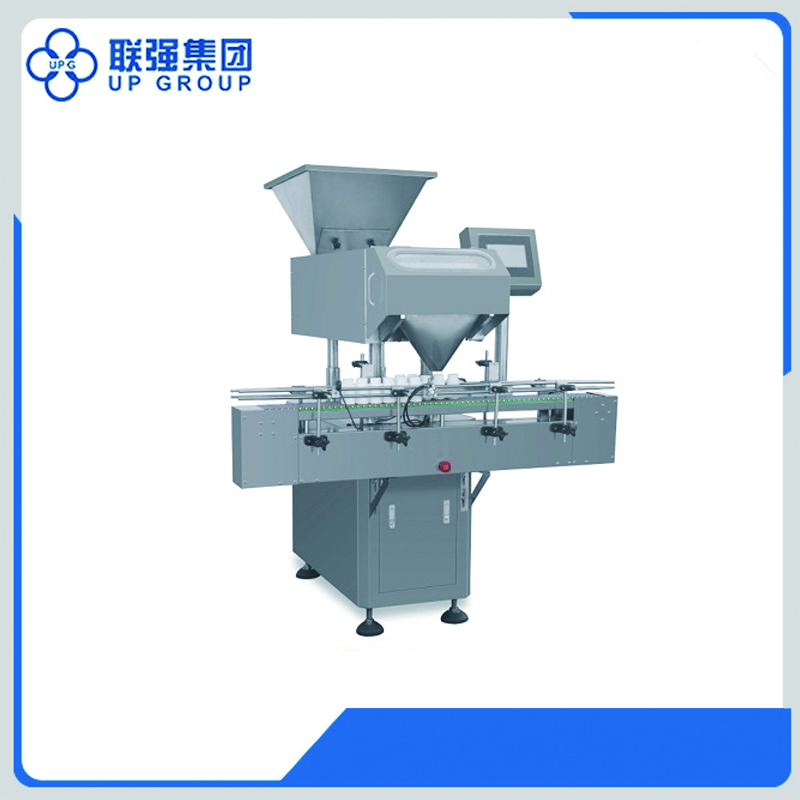

LQ-SLJS Electronic Counter

The block bottle device on the passing bottle-track of the conveying bottle system make the bottles which came from the previous equipment stay in the bottling position, waiting to be filled in. The medicine goes into the medicine container in order by the vibration of the feeding corrugated plate. There’s a counting photoelectric sensor installed on the medicine container, after counting of the medicine in the medicine container by the counting photoelectric sensor, the medicine goes into the bottle in the bottling position.