One of Hottest for Milk Powder Packaging Machine - LQ-XG Automatic Bottle Capping Machine – UPG

One of Hottest for Milk Powder Packaging Machine - LQ-XG Automatic Bottle Capping Machine – UPG Detail:

APPLY PHOTOS

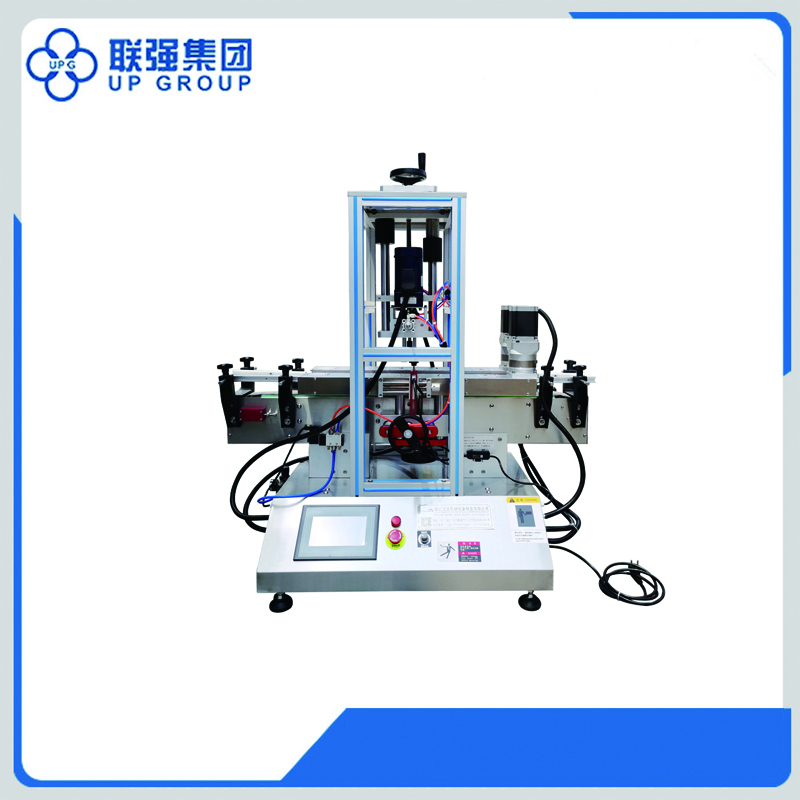

INTRODUCTION AND OPERATION PROCESS

Introduction:

This machine includes automatically cap sorting, cap feeding, and capping function. The bottles are entering in line, and then continuous capping, high efficiency. It’s widely used in industries of cosmetic, food, beverage, medicine, biotechnology, health care, personal care chemical and etc. it’s suitable for all kinds of bottles with screw caps.

On the other hand, it can connect with auto filling machine by conveyor. and also can connect with electromagetic sealing machine according to the customers’ requirements.

Operation Process:

Put the bottle on the conveyor by manual (or automatic feeding of the product by other device) – bottle delivery – put the cap on the bottle by manual or by caps feeding device - capping (automatic realized by the equipment)

TECHNICAL PARAMETER

|

Machine name |

LQ-XG Automatic Bottle Capping Machine |

|

Power supply |

220V, 50Hz, 850W, 1Ph |

|

Speed |

20 - 40 pcs/min (depend on the bottle size) |

|

Bottle diameter |

25 - 120 mm |

|

Bottle height |

100 – 300 mm |

|

Cap diameter |

25 - 100 mm |

|

Machine size |

L*W*H: 1200mm * 800mm * 1200mm |

|

Machine weight |

150 KG |

|

*Air compressor is provided by customer. *If the bottle and cap size are out of these range, please inform us. We can make the customized machine. |

|

FEATURE

1.The automatic capping machine is controlled by PLC, and the Chinese and English interface touch screen makes the operation display clear and easy to understand.

2. Ensure that the equipment is stable, reliable, torque consistent and easy to adjust even under long-term fatigue working condition.

3. The bottle clamping belt can be adjusted separately to make it suitable for the rubbing cover of bottles with different heights and shapes.

4. The whole machine is easy to adjust for different product size and different cap size.

5. The machine is light and convenient.

6. Easy operation and adjustment, low cost for maintain.

TERMS OF PAYMENT AND WARRANTY

Terms of Payment: 100% payment by T/T when confirming the order,or irrevocable L/C at sight.

Warranty: 12 months after B/L date.

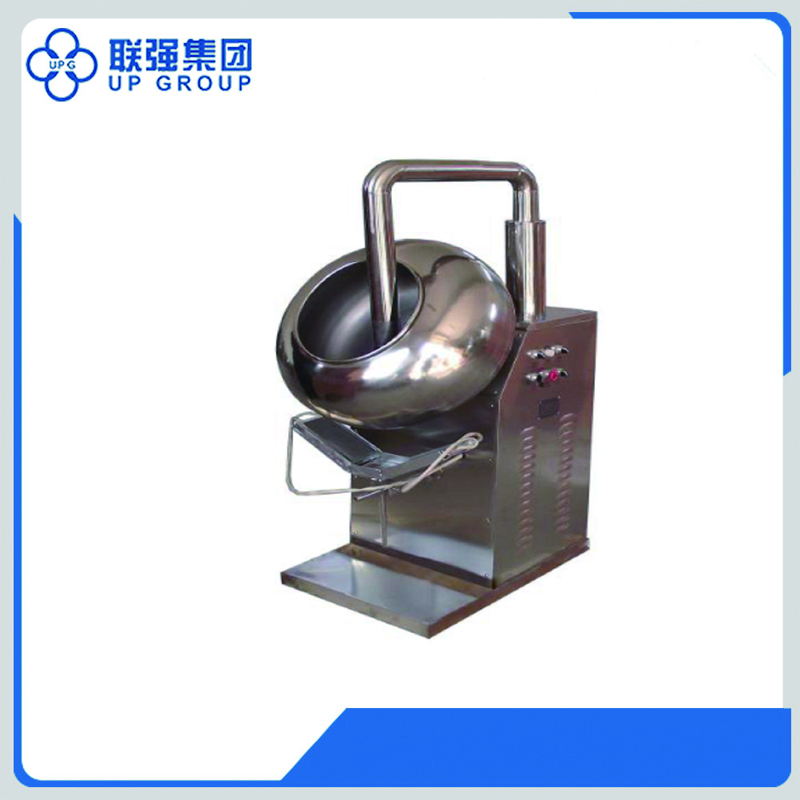

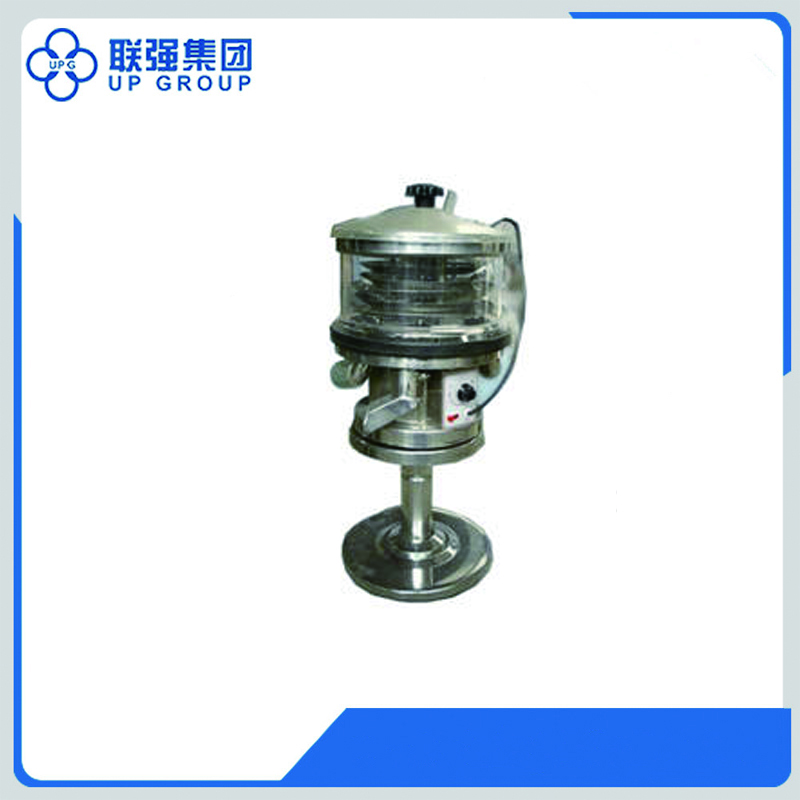

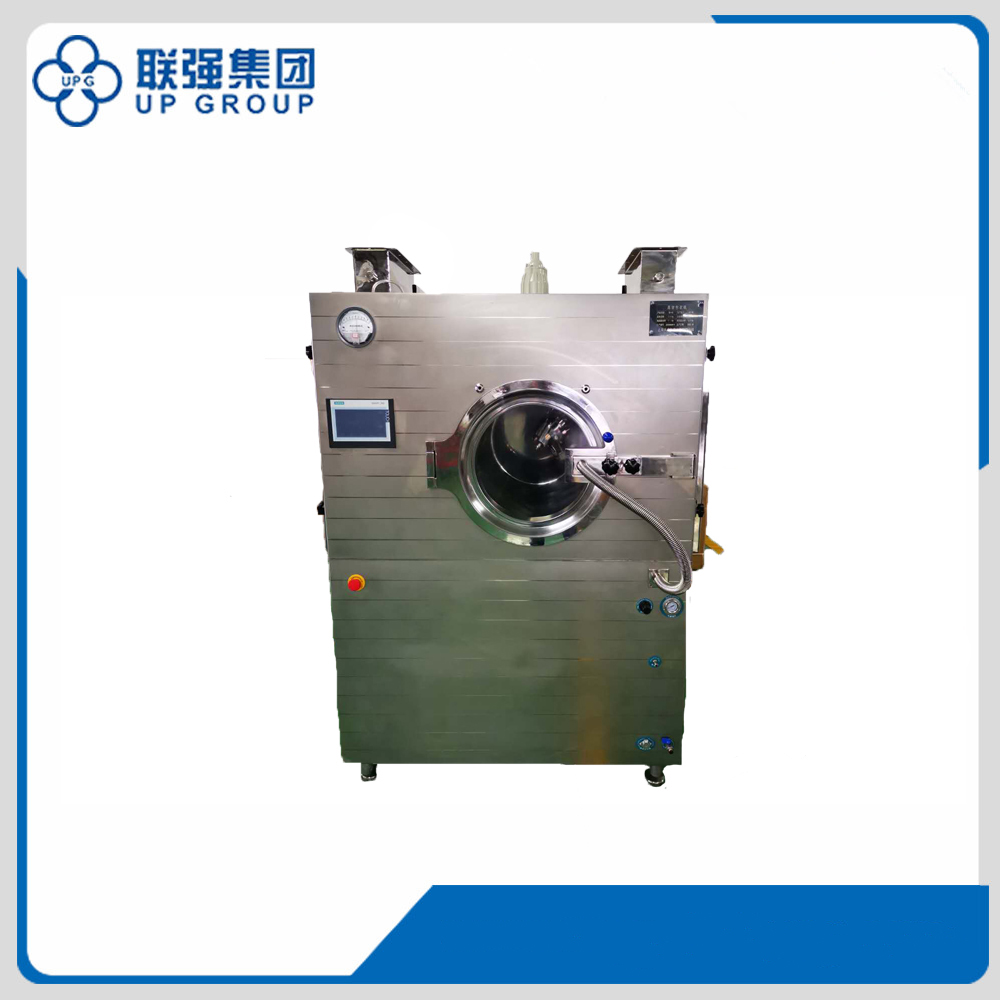

Product detail pictures:

Related Product Guide:

No matter new customer or previous client, We believe in prolonged time period and trustworthy relationship for One of Hottest for Milk Powder Packaging Machine - LQ-XG Automatic Bottle Capping Machine – UPG , The product will supply to all over the world, such as: Spain, London, Bahamas, Qualified R&D engineer will be there for your consultation service and we will try our best to meet your requirements. So please feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we will surely give you the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we will make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we are here to welcome your inquiries for any of our goods and service.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.