Renewable Design for Ampoule Blister Packing Machine - LQ-SLJS Electronic Counter – UPG

Renewable Design for Ampoule Blister Packing Machine - LQ-SLJS Electronic Counter – UPG Detail:

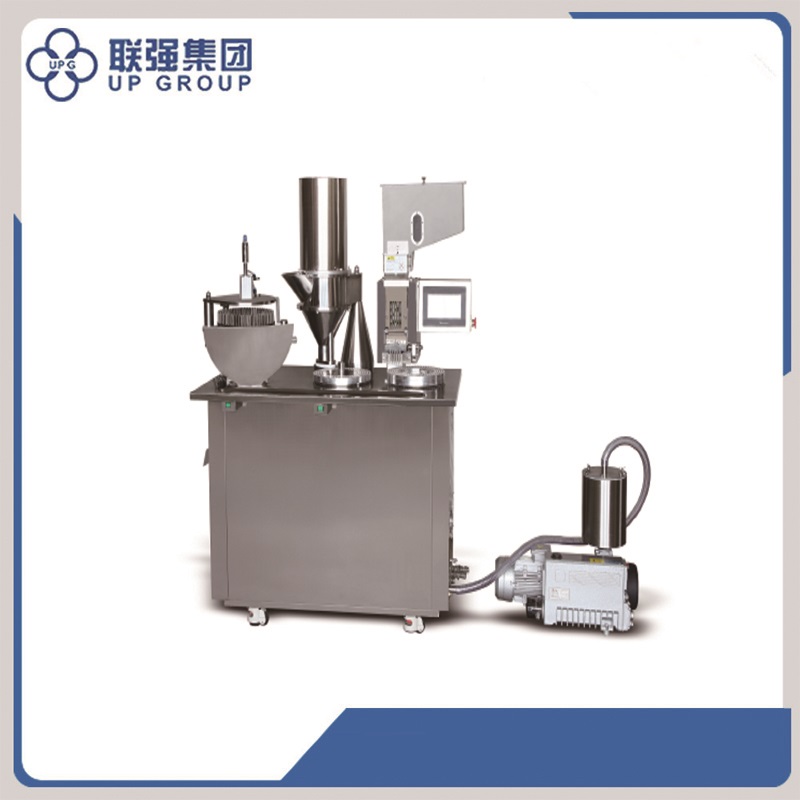

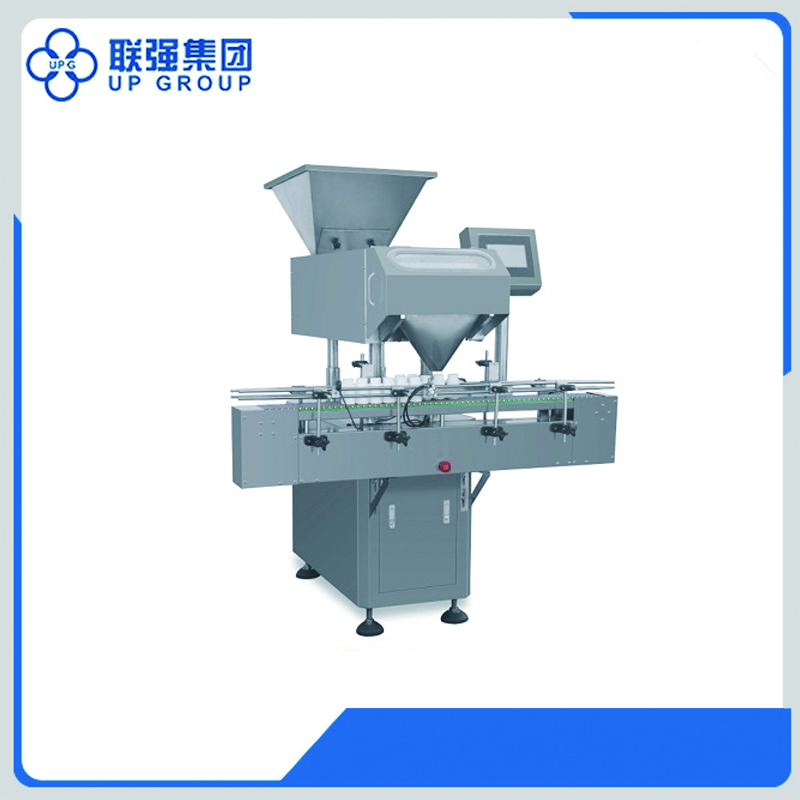

APPLY PHOTOS

PRODUCTION DESCRIPTION

The block bottle device on the passing bottle-track of the conveying bottle system make the bottles which came from the previous equipment stay in the bottling position, waiting to be filled in. The medicine goes into the medicine container in order by the vibration of the feeding corrugated plate. There’s a counting photoelectric sensor installed on the medicine container, after counting of the medicine in the medicine container by the counting photoelectric sensor, the medicine goes into the bottle in the bottling position.

TECHNICAL PARAMETER

|

Model |

LQ-SLJS 4-HEAD ELECTRONIC COUNTER |

LQ-SLJS 8-HEAD ELECTRONIC COUNTER |

If you need higher speed machine, please feel free to contact with me. |

|

Capacity |

About 20-25 bottles/min |

About 30-35 bottles/min |

|

|

Loading range |

1-9999 granules/tablets adjustable |

1-9999 granules/tablets adjustable |

|

|

Voltage |

220V,50Hz,1Ph |

220V,50Hz,1Ph |

|

|

Power |

0.6kw |

0.6kw |

|

|

Bottle size |

10~500ml round/flat bottle |

10~500ml round/flat bottle |

|

|

Counting accuracy |

More than 99.5% |

More than 99.5% |

|

|

Air source |

0.6 Mpa |

0.6 Mpa |

FEATURE

● Strong compatibility,It can count and bottle various kind of solid preparation or solid granules for example, tablet, capsule, soft capsule (transparent and non-transparent), pill etc.

● Vibration cutting: channel vibration under homogeneous materials, unique patent agencies blanking, turning out material is steady, not damage

● Anti high dust: Adopting the anti high dust photoelectric sensing technology only developed by our company, it also can work stably under the high dust circumstance.

● Correct counting: With automatic photoelectric sensor counting, the error of bottling is little.

● High intelligence: It has various alarm and control functions like no bottle no count.

● Easy operation: Adopting intellectualized design, all kinds of operation data can be set according to the requirement.

● Convenient maintenance: After simple training, the worker can operate easily. It is easy to disassembly, clean and change the components without any tools.

● Sealing and dust-proof: For tablet with high dust,dust collection box is available, it can reduce the dust pollution. (Optional)

TERMS OF PAYMENT AND WARRANTY

Terms of Payment:

30% deposit by T/T when confirming the order,70% balance by T/T before shipping. Or irrevocable L/C at sight.

Warranty:

12 months after B/L date.

Product detail pictures:

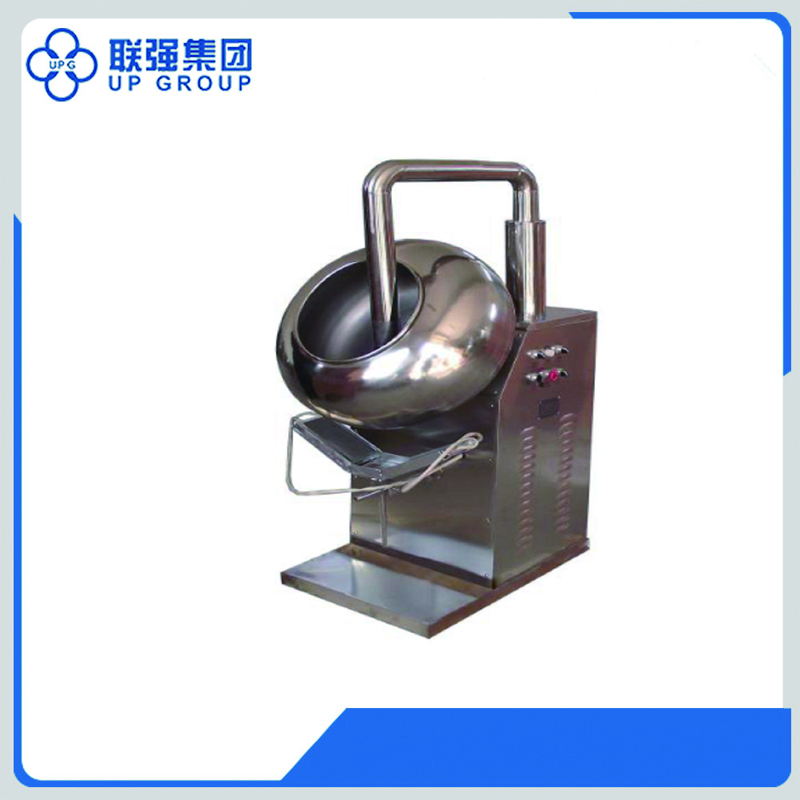

Related Product Guide:

We've numerous great employees customers excellent at promoting, QC, and working with kinds of troublesome difficulty inside the generation method for Renewable Design for Ampoule Blister Packing Machine - LQ-SLJS Electronic Counter – UPG , The product will supply to all over the world, such as: Ecuador, Slovakia, Czech, Why we can do these? Because: A, We are honest and reliable. Our items have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage . C, Various types: Welcome your inquiry, It might be highly appreciated.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!