-

LQ-DC-2 Drip Coffee Packaging Machine (High Level)

This high level machine is the latest design based on the general standard model, specially design for different kinds of drip coffee bag packing. The machine adopts fully ultrasonic sealing, compared with the heating sealing, it has the better packaging performance, besides, with the special weighing system: Slide doser, it effectively avoided the waste of coffee powder.

-

LQ-DC-1 Drip Coffee Packaging Machine (Standard Level)

This packaging machine is suitable for drip coffee bag with outer envelope,and it is available with coffee, tea leaves, herbal tea, health care tea, roots, and other small granule products. The standard machine adopts the fully ultrasonic sealing for inner bag and heating sealing for outer bag.

-

LQ-ZP-400 Bottle Capping Machine

This automatic rotary plate capping machine is our new designed product recently. It adopts rotary plate to positioning the bottle and capping. The type machine is widely used in packaging cosmetic, chemical, foods, pharmaceutical, pesticides industry and so on. Besides plastic cap, it is workable for the metal caps as well.

The machine is controlled by air and electricity. The working surface is protected by stainless steel. The whole machine meets the requirements of GMP.

The machine adopts mechanical transmission, transmission accuracy, smooth, with low loss, smooth work, stable output and other advantages, especially suitable for batch production.

-

LQ-TFS Semi-auto Tube Filling and Sealing Machine

This machine applies the once transmission principle. It uses the slot wheel dividing system to drive the table to do intermittent movement. The machine has 8 sits. Expect manually putting the tubes on the machine, it can automatically fill the material into the tubes, heat both inside and outside of the tubes, seal the tubes, press the codes, and cut the tails and exit the finished tubes.

-

LQ-BTA-450/LQ-BTA-450A+LQ-BM-500 Automatic L Type Shrink Wrapping Machine

1. BTA-450 is an economical fully-auto operation L sealer by our company’s independent research and development, which is widely used in mass production assembly line with auto-feeding, conveying, sealing, shrinking in one time. It is high working efficiency and suits for the products of different height and width;

2. The horizontal blade of sealing part adopts vertical driving, while the vertical cutter uses international advanced thermostatic side cutter; The sealing line is straight and strong and we can guarantee seal line in the middle of the product to achieve perfect sealing effect;

-

LQ-BKL Series Semi-auto Granule Packing Machine

LQ-BKL series semi-auto granule packing machine is specially developed for granular materials and designed strictly according to GMP standard. It could finish weighing, filling automatically. It is suitable for all kinds of granular foods and condiments such as white sugar, salt, seed, rice, aginomoto, milk powder, coffee, sesame and washing powder.

-

LQ-BTB-300A/LQ-BTB-350 Overwrapping Machine For Box

This machine is widely applicable to the automatic film packaging (with gold tear tape) of various single boxed articles. With new-type of double safeguard, no need to stop the machine, other spare parts will not be damaged when the machine runs out of step. Original unilateral hand swing device to prevent adverse shaking of the machine,And the non-rotation of the hand wheel when the machine keeps running to secure the security of the operator. No need to adjust the height of worktops on both sides of the machine when you need to replace moulds, no need to assemble or dismantle the material discharge chains and discharge hopper.

-

LQ-LF Single Head Vertical Liquid Filling Machine

Piston fillers are designed to dispense a wide variety of liquid and semi-liquid products. It serves as ideal filling machines for the cosmetic, pharmaceutical, food, pesticide and other industries. They are completely powered by air, which makes them especially suitable for an explosion-resistant or moist production environment. All the components that come in contact with product are made of 304 stainless steel, processed by CNC machines. And the surface roughness of which are ensured to be lower than 0.8. It is these high quality components that help our machines achieve market leadership when compared with other domestic machines of the same type.

Delivery time: Within 14 days.

-

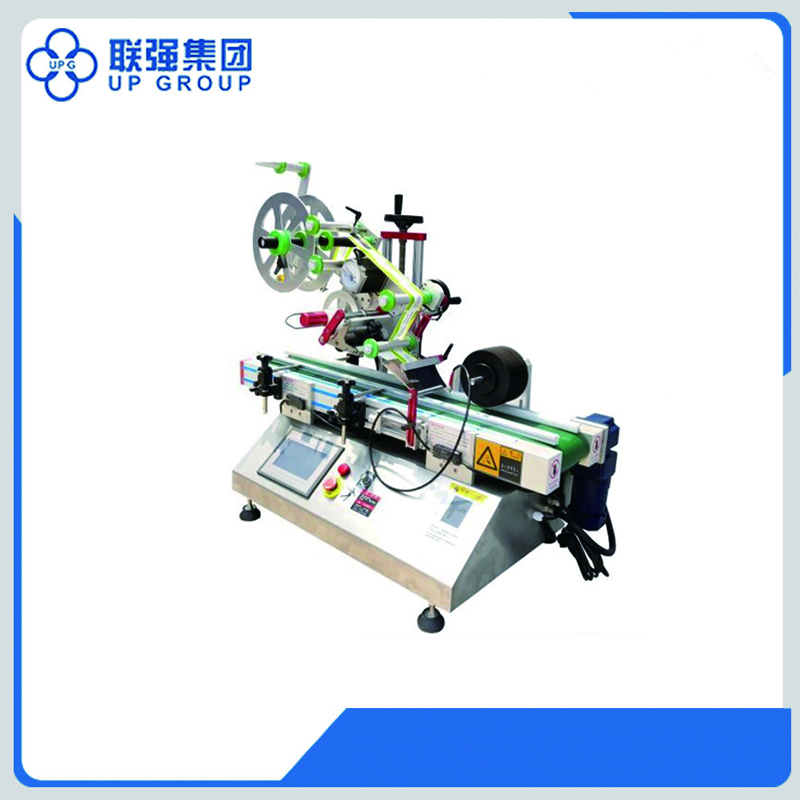

LQ-FL Flat Labeling Machine

This machine is used to label the adhesive label on the flat surface.

Application industry: widely used in food, toys, daily chemicals, electronics, medicine, hardware, plastics, stationery, printing and other industries.

Applicable labels: paper labels, transparent labels, metal labels etc.

Application examples: carton labeling, SD card labeling, electronic accessories labeling, carton labeling, flat bottle labeling, ice cream box labeling, foundation box labeling etc.

Delivery time: Within 7 days.

-

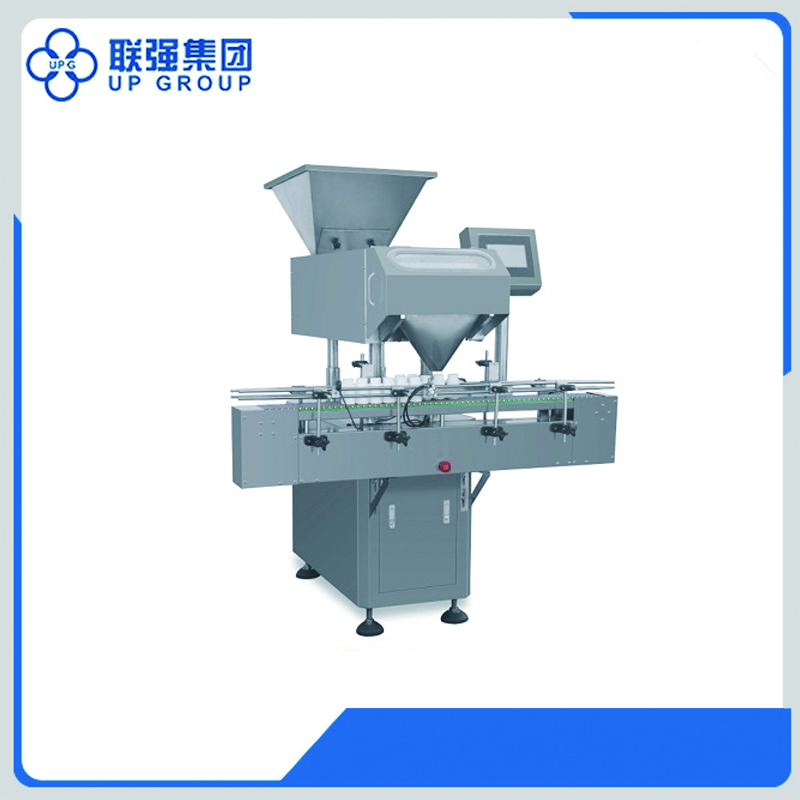

LQ-SLJS Electronic Counter

The block bottle device on the passing bottle-track of the conveying bottle system make the bottles which came from the previous equipment stay in the bottling position, waiting to be filled in. The medicine goes into the medicine container in order by the vibration of the feeding corrugated plate. There’s a counting photoelectric sensor installed on the medicine container, after counting of the medicine in the medicine container by the counting photoelectric sensor, the medicine goes into the bottle in the bottling position.

-

LQ-CC Coffee Capsule Filling and Sealing Machine

The coffee capsule filling machines are specifically designed for the needs of specialty coffee packing to provide more possibilities to ensure the freshness and shelf life of coffee capsules. The compact design of these coffee capsule filling machine allows for maximum space usage whilst saving labor cost.

-

LQ-ZHJ Automatic Cartoning Machine

This machine is suitable for packing blisters, tubes, ampules and other related objects into boxes. This machine can fold leaflet, open box, insert blister into box, emboss batch number and close box automatically. It adopts frequency inverter to adjust speed, human machine interface to operate, PLC to control and photoelectric to supervise and control each station the reasons automatically, which can solve the troubles in time. This machine can be used separately and also can be linked with other machines to be a production line. This machine can also be equipped with hot melt glue device to do hot melt glue sealing for box.