Free sample for Shrink Packing Machine - LQ-RL Automatic Round Bottle Labeling Machine – UPG

Free sample for Shrink Packing Machine - LQ-RL Automatic Round Bottle Labeling Machine – UPG Detail:

APPLY PHOTOS

INTRODUCTION

● Applicable labels: self-adhesive label, self-adhesive film, electronic supervision code, bar code, etc.

● Applicable products: products requiring labels or films on the circumferential surface.

● Application Industry: widely used in food, toys, daily chemicals, electronics, medicine, hardware, plastics and other industries.

● Application examples: PET round bottle labeling, plastic bottle labeling, mineral water labeling, glass round bottle, etc.

TECHNICAL PARAMETER

| Machine name | LQ-RL Automatic Round Bottle Labeling Machine |

| Power supply | 220V / 50Hz / 1kw / 1Ph |

| Speed | 40-50 pcs/min |

| Labeling accuracy | ±1 mm |

| Product size | Dia.:20-80 mm |

| Label size | W:15-140 mm,L:≧20 mm |

| Inner roll | 76 mm |

| Outer roll | 300 mm |

| Machine size | 2000mm * 1000mm * 900mm |

| Machine weight | 200 KG |

FEATURE

1. High labeling accuracy, good stability, flat labeling, no wrinkling and no bubbles;

2. The labeling speed, conveying speed and bottle separation speed can realize stepless speed regulation, which is convenient for the production personnel to adjust according to the actual needs;

3. The bottle stand-by labeling is adopted, which can be produced by a single machine or connected to an assembly line to realize unmanned labeling production;

4 . Stable mechanical structure and stable operation;

5. It has automatic bottle separation function, excessive bottle storage buffer function, circumferential positioning and labeling function, and each function can be freely selected on demand through the human-computer interaction interface;

6. The structural combination of mechanical adjustment part and the ingenious design of label winding make it convenient to fine tune the degree of freedom of labeling position (it can be completely fixed after adjustment), which makes the conversion between different products and label winding simple and time-saving; It has the function of no labeling without objects;

7. The main materials of the equipment are stainless steel and high-grade aluminum alloy, with firm overall structure and elegant appearance;

8. It is controlled by standard PLC + touch screen + stepping motor + standard sensor electronic control system, with high safety factor, convenient use and simple maintenance;

9. Complete equipment supporting data (including equipment structure, principle, operation, maintenance, repair, upgrading and other explanatory data) to provide sufficient guarantee for the normal operation of the equipment;

10. With production counting function.

TERMS OF PAYMENT AND WARRANTY

Terms of Payment:

100% payment by T/T when confirming the order. Or irrevocable L/C at sight.

Warranty:

12 months after B/L date.

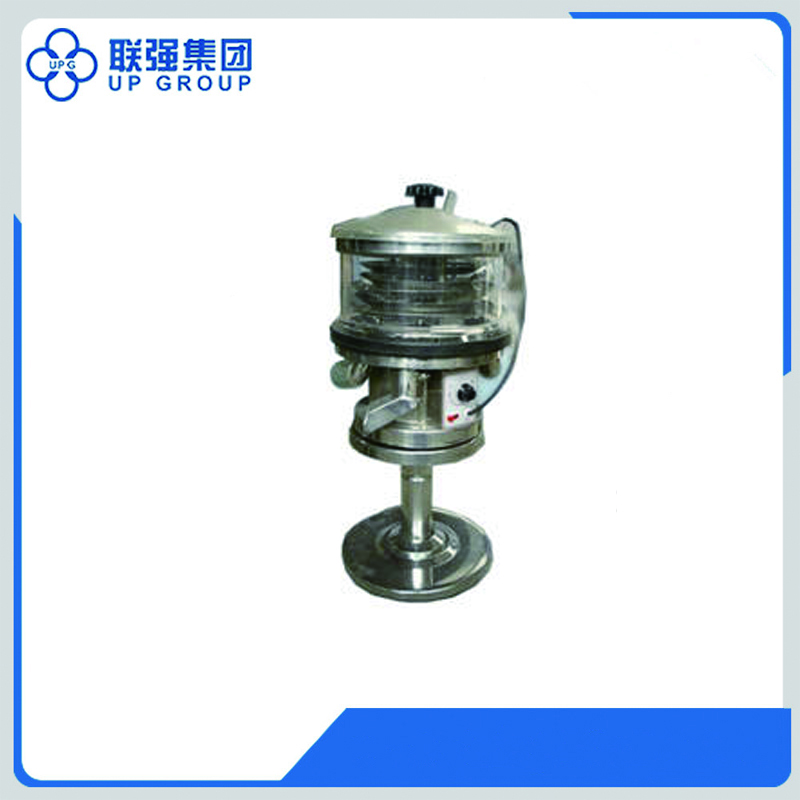

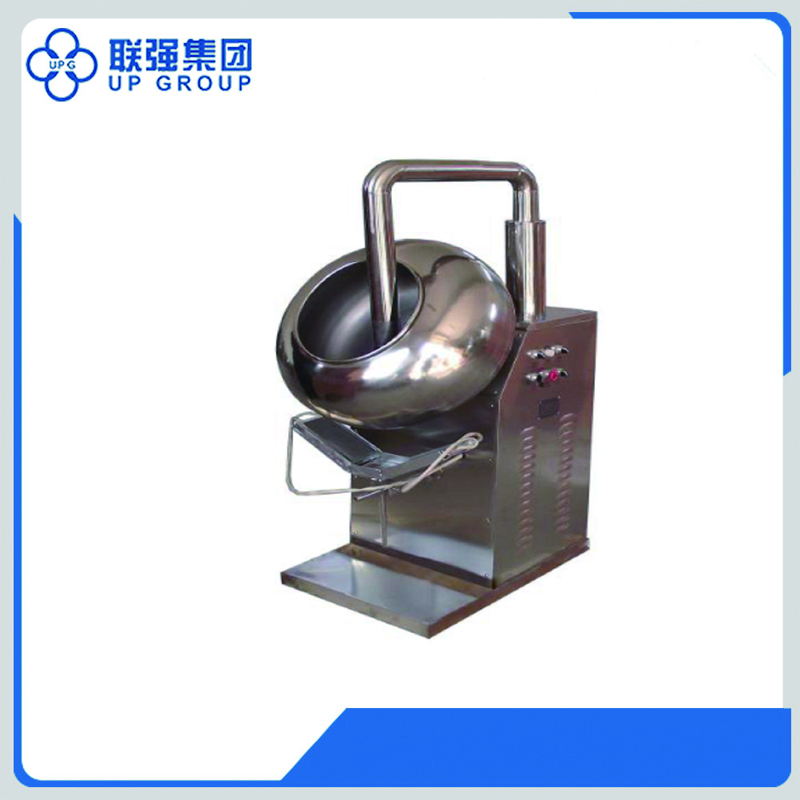

Product detail pictures:

Related Product Guide:

We believe that long term partnership is a result of high quality, value added service, rich experience and personal contact for Free sample for Shrink Packing Machine - LQ-RL Automatic Round Bottle Labeling Machine – UPG , The product will supply to all over the world, such as: Leicester, Detroit, Accra, Till now, the goods list has been updated regularly and attracted clients from around the globe. Detailed facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are going to help you get comprehensive acknowledge about our products and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.