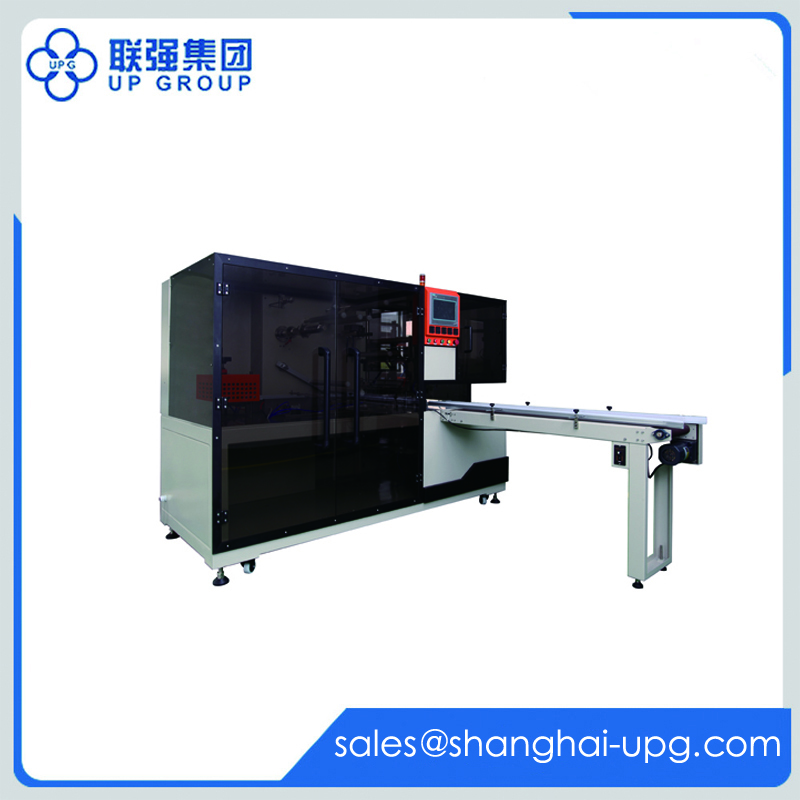

Factory directly Rotary Packing Machinery - LQ-BLG Series Semi-auto Screw Filling Machine – UPG

Factory directly Rotary Packing Machinery - LQ-BLG Series Semi-auto Screw Filling Machine – UPG Detail:

APPLY PHOTOS

INTRODUCTION

LG-BLG series semi-auto screw filling machine is designed according to the standards of Chinese National GMP. Filling, weighing can be finished automatically. The machine is suitable for packing powdery products such as milk powder, rice powder, white sugar, coffee, monosodium, solid beverage, dextrose, solid medicament, etc.

TECHNICAL PARAMETER

| Model | LQ-BLG-1A3 | LQ-BLG-1B3 |

| Metering Mode | Auger rotation filling traced by weighing feedback | |

| Packing Weight Range | 1-500g | 10-5000g |

| The screw attachment | The screw attachment | |

| should be changed | should be changed | |

| Filling Accuracy | ±0.3-1%(According to packing weight and product specifications) | |

| Hopper Volume | 26L | 50L |

| Production Capacity | 20-60bags/min | 15-50bags/min |

| Total Power | 1.3kw | 1.8kw |

| Power Supply | 380V/220V 50-60HZ | |

| Overall Dimensions | 850*750*1900mm | 1000*1300*2200mm |

| Net Weight | 150kg | 260kg |

FEATURE

1. The whole machine is made of 304 stainless steel in addition to the servo motor and other accessories which completely meet the requirement of GMP and other food sanitation certification.

2. HMI using PLC plus touch screen: PLC has better stability and higher weighing precision, as well as interference-free. Touch screen result in easy operation and clear control. Human-computer-interface with PLC touch screen which have the features of stable working, high weighing precision, anti-interference. The PLC touch screen is easy to operate and intuitive. Weighing feedback and proportion tracking overcome the disadvantage of the package weight changes due to the material proportion difference.

3. The filling system is driven by servo-motor which have the features of high precision, large torque, long service life and the rotation could be set as requirement.

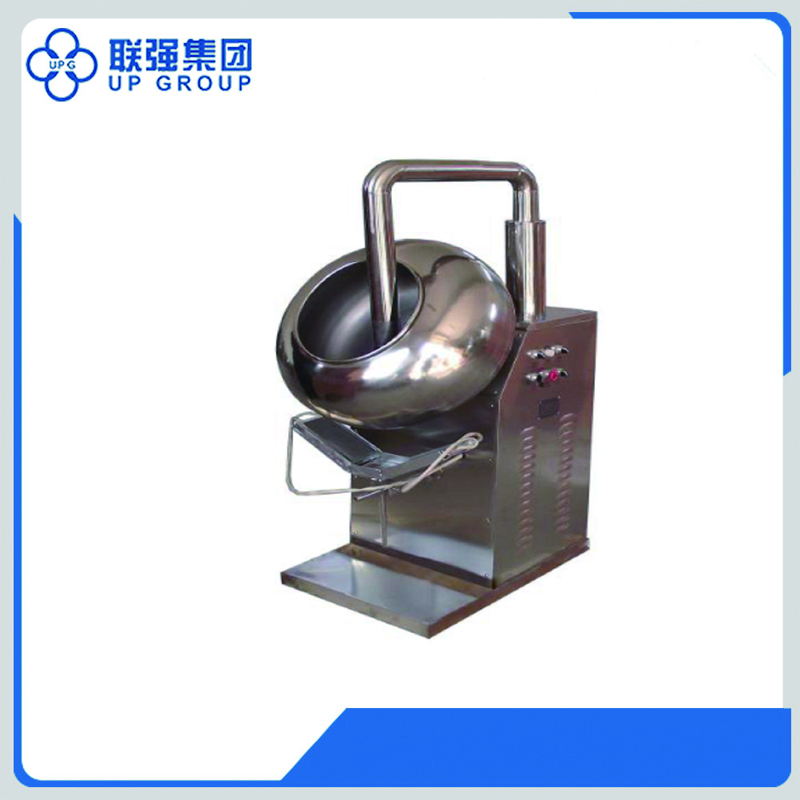

4. The agitate system assemble with the reducer which is made in Taiwan and with the features of low noise, long service life, maintenance-free for all its life.

5. Maximum 10 formulas of products and adjusted parameters can be saved for later using.

6. The cabinet is made in 304 stainless steel and fully closed with visual organic glass and air-damping. The activity of the product inside the cabinet could be seen clearly, the powder will not leak out of the cabinet. The filling outlet is equipped with the dust-remove device that can protect the environment of the workshop.

7. By changing the screw accessories, the machine can be suitable for multiple products, no matter super fine power or large granules.

TERMS OF PAYMENT AND WARRANTY

Terms of Payment:

30% deposit by T/T when confirming the order,70% balance by T/T before shipping. Or irrevocable L/C at sight.

Warranty:

12 months after B/L date.

Product detail pictures:

Related Product Guide:

We insist on offering good quality generation with very good business enterprise concept, honest income as well as best and fast assistance. it will bring you not only the premium quality product or service and huge profit, but probably the most significant is usually to occupy the endless market for Factory directly Rotary Packing Machinery - LQ-BLG Series Semi-auto Screw Filling Machine – UPG , The product will supply to all over the world, such as: Honduras, Pakistan, San Francisco, Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to offer our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We are ready to face the worries and make the improve to understand all the possibilities in international trade.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.