18 Years Factory Shrink Sleeve Labeling Machine - LQ-CFQ Deduster – UPG

18 Years Factory Shrink Sleeve Labeling Machine - LQ-CFQ Deduster – UPG Detail:

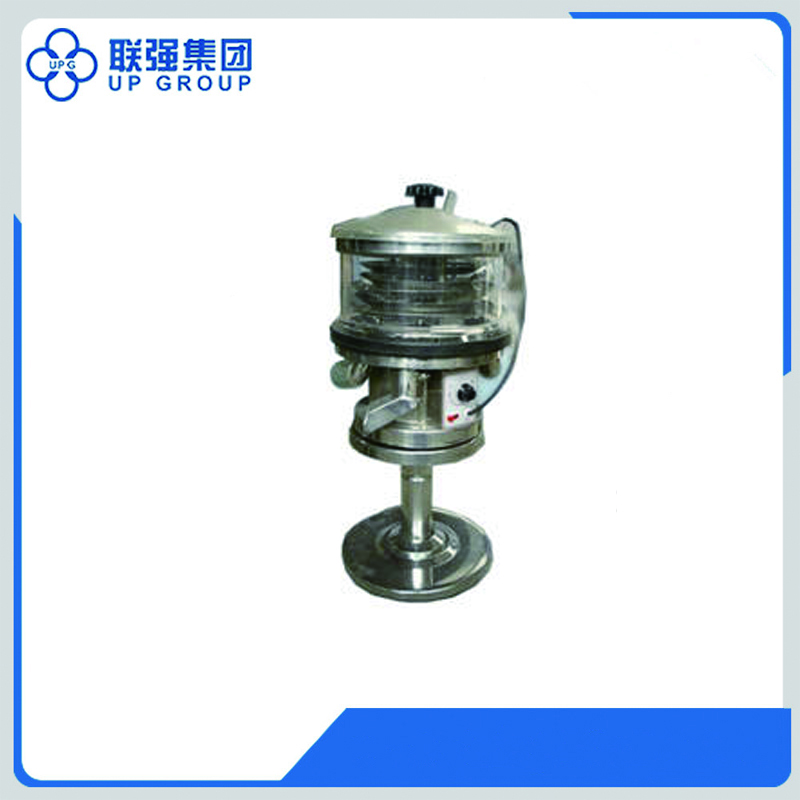

INTRODUCTION

The LQ-CFQ deduster is an auxiliary mechanism of high tablet press to remove some powder stuck on surface of tablets in pressing process. It is also equipment for conveying tablets, lump drugs, or granules without dust and can be suitable for joining with an absorber or a blower as a vacuum cleaner. It has high efficiency, better dust-free effect, lower noise, and easy maintenance. The LQ-CFQ deduster is widely used in pharmaceutical, chemical, food industry, etc.

MAIN CHARACTERISTIC

1. Design of GMP.

2. Double layers screen structure, separating tablet & powder.

3. V-shape design for the powder-screening disk, polished efficiently.

4. Speed and amplitude adjustable.

5. Easily operating and maintaining.

6. Operating reliably and low noise.

TECHNICAL PARAMETER

| Model | LQ-CFQ |

| Capacity | 550000 pcs/h |

| Max.Noise | <82 dB |

| Atmospheric Pressure | 0.2 MPa |

| Voltage | 220V/50Hz/50w |

| Overall Dimension(L*W*H) | 410mm*410mm*880mm |

| Net Weight | 34 kg |

TERMS OF PAYMENT AND WARRANTY

Terms of Payment:

100% payment by T/T when confirming the order,or irrevocable L/C at sight.

Warranty:

12 months after B/L date.

Product detail pictures:

Related Product Guide:

"Quality initially, Honesty as base, Sincere company and mutual profit" is our idea, in order to create repeatedly and pursue the excellence for 18 Years Factory Shrink Sleeve Labeling Machine - LQ-CFQ Deduster – UPG , The product will supply to all over the world, such as: Saudi Arabia, Turin, Serbia, Since the establishment of our company, we've realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question points they do not understand. We break down these barriers to ensure you get what you want to the level you expect, when you want it.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!